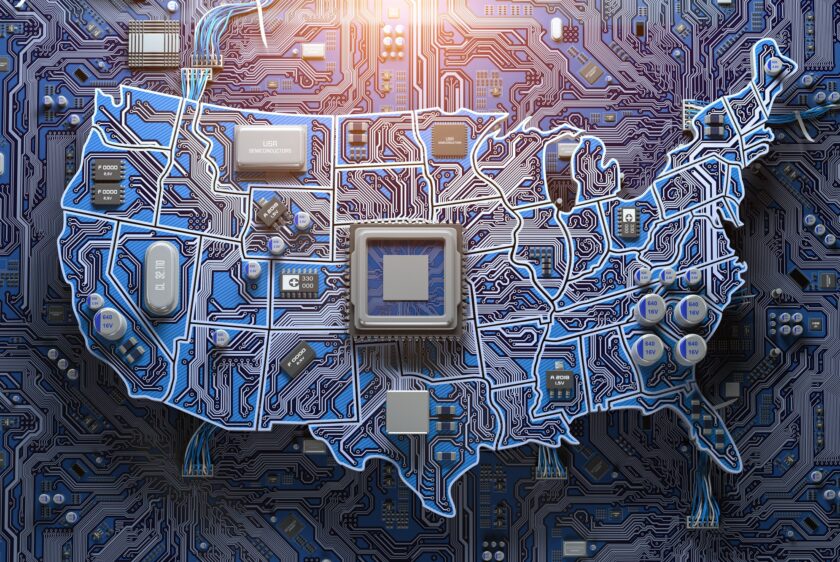

A Strategic Shift in Electronics Manufacturing

The global supply chain disruptions, geopolitical instability, and intellectual property protection risks associated with offshoring have forced companies to rethink their reliance on overseas production. As a result, reshoring electronics manufacturing has emerged as a competitive advantage, ensuring greater control, supply chain resilience, and high-quality products.

For companies looking to bring their electronics manufacturing back to the home country, Southern California presents an unmatched opportunity. With a strong infrastructure, skilled workforce, and robust regulatory compliance, this region is setting the standard for domestic production—and Electro Surface Technologies (EST) is leading the charge.

Southern California: The Epicenter of Innovation & Manufacturing Excellence

Proximity to Leading Innovation Hubs

Located near Silicon Valley, Los Angeles, and San Diego, Southern California offers unparalleled access to the world’s most advanced electronics manufacturing ecosystems. This proximity fosters faster prototyping, collaborative engineering, and seamless product development—all critical factors for high-tech industries.

📌 EST Advantage: Our San Diego-based facility works directly with OEMs, startups, and industry leaders, ensuring rapid innovation and time-to-market efficiency.

A Highly Skilled Workforce for Complex Electronics

One of the biggest challenges in reshoring efforts is finding skilled labor capable of handling high-precision electronics manufacturing. Southern California is home to engineers, SMT specialists, and photonics experts with deep expertise in:

✅ Surface Mount Technology (SMT) & Through-Hole Technology (THT)

✅ High-mix, low-to-medium volume production

✅ Complex photonics & mission-critical electronics assembly

📌 EST Advantage: Our team specializes in custom electronics manufacturing, supporting industries like medical devices, aerospace, and defense, where failure is not an option.

Regulatory Excellence & Compliance: A Reshoring Imperative

For electronics manufacturers, one of the key advantages of reshoring production to the San Diego area is regulatory compliance. Unlike low-cost countries, where quality control issues and compliance risks are rampant, U.S. contract manufacturers adhere to strict industry standards.

Key Compliance Benefits:

✅ ISO 13485 Certification: Essential for medical device manufacturing, ensuring audit-ready quality management systems.

✅ ITAR Compliance: Required for defense and aerospace manufacturing, ensuring national security regulations are met.

✅ FDA Registration: Necessary for biotech, medical devices, and healthcare technology, streamlining market entry.

📌 EST Advantage: We operate a fully compliant, ITAR-registered, ISO 9001 & ISO 13485-certified facility, ensuring your electronics manufacturing meets the highest industry standards.

Addressing Supply Chain Challenges & Global Instability

Mitigating Global Supply Chain Disruptions

The past decade has proven that offshoring comes with serious risks, including:

❌ Geopolitical instability affecting production timelines

❌ Supply chain bottlenecks leading to unpredictable delays

❌ IP security vulnerabilities and counterfeiting risks

By reshoring electronics manufacturing, companies gain:

✅ Faster turnaround times & improved lead-time predictability

✅ Stronger supply chain management with fewer disruptions

✅ Full transparency & greater control over production

📌 EST Advantage: Our San Diego-based contract manufacturing service eliminates offshore risks, providing a secure, ITAR-compliant, U.S.-based solution.

High-Mix, Low-Volume Production: Supporting Startups & OEMs

Unlike traditional mass production EMS providers, Southern California’s contract manufacturers specialize in high-mix, low-to-medium volume production—ideal for:

✅ Hardware startups launching new products

✅ OEMs requiring flexible, small-batch production

✅ Prototyping-to-production transitions with minimal risk

📌 EST Advantage: We provide custom manufacturing solutions without the high MOQs (Minimum Order Quantities) typically required by overseas vendors.

Strategic, Long-Term Partnerships Over Transactional Vendor Relationships

The true value of reshoring efforts isn’t just about bringing production back home—it’s about partnering with the right company that understands your business goals. Unlike offshore EMS providers focused purely on low-cost, high-volume production, Southern California manufacturers like EST offer:

✅ Dedicated Program Management—Ensuring seamless project alignment with your long-term vision.

✅ Risk Mitigation Strategies—Helping companies navigate complex production challenges.

✅ Multi-Year Agreements—Fostering stability, continuous improvement, and product innovation.

📌 EST Advantage: We don’t just build products—we become an extension of your engineering team, supporting long-term growth and market success.

Why Companies Are Choosing Southern California for Reshoring Electronics Manufacturing

As global uncertainties, compliance risks, and IP security concerns continue to challenge the industry, reshoring electronics manufacturing to Southern California offers:

✔ Greater control over production, supply chain management, and quality assurance

✔ Stronger intellectual property protection compared to low-cost countries

✔ High-quality products manufactured under strict compliance standards

✔ Proximity to innovation hubs, skilled labor, and U.S. R&D infrastructure

📌 The EST Difference: As a leading U.S. contract manufacturer, Electro Surface Technologies provides fully compliant, high-precision electronics manufacturing solutions that eliminate offshore risks while maximizing production efficiency.

📞 Request a Quote Today – Get a Response in 24 Hours!