In high-reliability sectors like medical technology, aerospace, defense, and industrial electronics, one flaw isn’t just a quality issue—it’s a business risk. A single failure can compromise safety, security, or regulatory approval.

At Electro Surface Technologies (EST), we don’t just build electronics—we build trust. This article outlines the systems, decision-makers, and capabilities that make us a reliable partner for the most demanding programs on earth.

Compliance Is Just the Starting Line

In regulated industries, compliance is a critical component. But mere check-the-box compliance isn’t enough.

We specialize in ISO 13485, ITAR, and FDA-compliant manufacturing—and we treat these frameworks not as constraints but as critical systems for risk prevention and quality assurance. With over 35 years of quality management experience and a history of zero major findings in independent audits, EST brings a culture of zero-compromise execution.

Our clients know their builds are audit-ready, ensuring alignment and confident decision-making every time.

Why U.S.-Based Manufacturing Still Matters

Offshore production may lower unit costs—but it often introduces unacceptable risk: from IP exposure and geopolitical instability to shipping delays and quality drift.

That’s why we manufacture exclusively in San Diego, California. Our ITAR-compliant facilities deliver full production transparency, enhanced security, and tighter turnaround times—all backed by a U.S. labor force trained in high-reliability practices.

For defense, aerospace, and companies reshoring critical infrastructure, EST offers a secure, scalable domestic alternative that supports both innovation and compliance. Our U.S.-based operations ensure the best user experience and customer value by minimizing potential setbacks tied to offshore production.

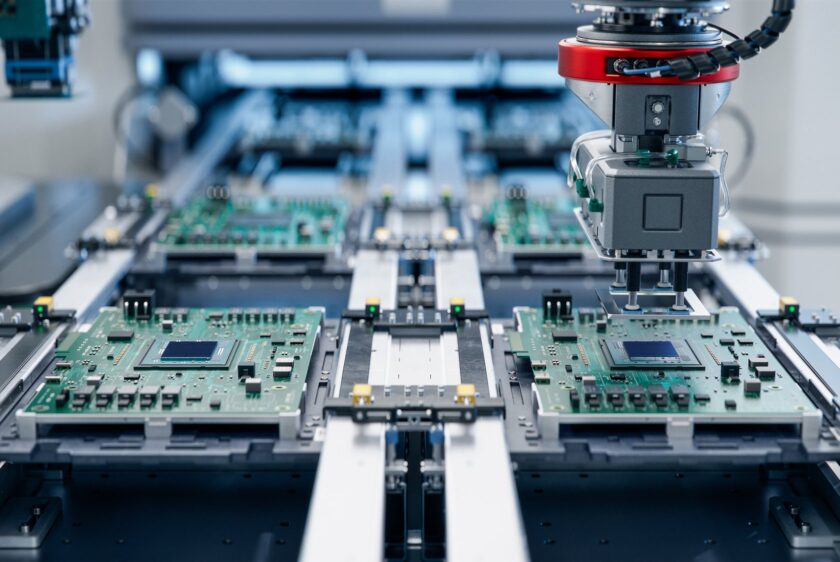

Built for High-Mix, Low-Volume Precision

Not every project fits a high-volume model. We specialize in low-to-mid volume builds that demand customization, flexibility, and technical fluency.

Our expertise in SMT, THT, and complex photonics enables us to build assemblies others can’t—or won’t—touch. We don’t require large MOQs, and our team is fluent in pivoting between prototypes and production runs without sacrificing quality or speed.

This model is especially valuable for fast-moving sectors like IoT, AI, and medtech, where adaptability and continuous learning are often the differentiators between launch and lag. By enabling a seamless transition, we support effective project development and ensure optimal output.

From Prototype to Production—Without the Drop-Off

Most contract manufacturers force startups and scale-ups to navigate a handoff gap between prototyping and production. EST eliminates that tension and friction.

We support early-stage engineering teams with DFM input, build process consultation, and fast-turn prototypes—all within the same facility that will scale their production.

Our integrated model shortens development timelines, minimizes redesign cycles, and helps get regulated products to market faster—with fewer surprises along the way, reinforcing trust and business success.

Strategic Partnership, Not Just Parts on a Line

We’re not a transactional vendor. We embed with our partners—especially during complex, time-sensitive builds.

That means hands-on program management, supply chain foresight, and cross-functional collaboration with engineering and procurement teams. Through fostering collaboration, we offer informed decisions at every stage of the development process.

This is why many of our relationships span decades—and why both startups and OEMs trust us with their most critical programs. Our project managers ensure consistent project alignment and constructive feedback, securing a confident team environment.

Sector-Specific Reliability—What It Really Looks Like

Medical & Healthcare Technology

Precision and documentation aren’t negotiable. EST’s ISO 13485-certified processes and cleanroom capabilities ensure builds that are ready for FDA scrutiny and life-critical applications.

Defense & Aerospace

Every part serialized. Every step documented. Our ITAR-compliant facilities meet the traceability and environmental durability requirements these sectors demand, mitigating conception failures and execution failures.

Industrial & Energy Electronics

We build for rugged use and extreme conditions—supporting robotics, automation, and smart energy systems with assemblies that don’t flinch under stress.

Comms & IT Infrastructure

Next-gen networks require secure, high-precision electronics. We support 5G, IoT, and AI-enabled devices with U.S.-based, IP-secure manufacturing and fast-turn capabilities.

High-End Consumer Technology

Premium products require premium execution. We help visionary brands go to market with fast-turn prototypes and flawless fit-and-finish—even in small runs.

Early-Stage Startups

Founders need flexibility. We provide prototyping, DFM mentorship, and supply chain stability—giving hardware startups a realistic path from concept to scale. Our expertise aids in reducing tension and setbacks, fostering empowered teams.

Mid-Sized OEMs

OEMs trust EST to deliver repeatable quality without high-volume constraints. Our mature systems, onshore agility, and engineering support help keep programs on track, solidifying the pathway to business success.

Final Word

Reliability isn’t just a feature—it’s a promise. At EST, it’s a product of our systems, our people, and our priorities. From regulatory mastery to build precision, from onshore security to startup-friendly flexibility, everything we do is designed to protect one thing: your reputation.

Let’s build something you can trust by leveraging our mastery, continuous learning, and actionable steps designed for a successful product manager.